All combustible dusts can cause an explosion as soon as the particle diameter is less than 500 µm. This is a general phenomenon known for a long time.

In most of industrial countries in the world there is an average of one dust explosion per day. The risk has been amplified by increasing industrialization, mechanization, the generalization of automatic systems, increased storage capacity, the increase in handling systems and finally the ever-increasing number of powdery products with ever-smaller particle sizes.

Industrial workers handling organic chemical or metallic powders will therefore face a potential risk of dust ignition and explosion. Prevention will first require knowledge of the explosive characteristics of dusts, it will then aim first, to avoid the formation of an explosive atmosphere, second, to avoid the ignition of the explosive atmosphere and finally, if the explosion occurs, to minimize its effects. (Source INRS: Explosive mixtures - 2. Combustible dusts - Ref. ED944).

It is precisely in this area that ATEX CONSULTING works by offering systems aimed at minimizing the effects of an air/dust explosion when it occurs.

We can protect installations from the consequences of an explosion by building equipment resisting 10 bar pressure or by discharging the explosion through a weaker surface (explosion vent) or by suppressing the explosion.

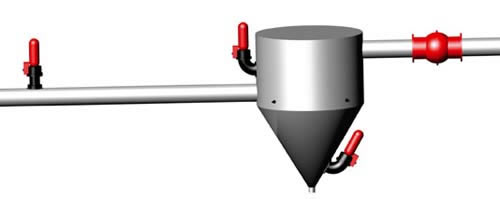

In addition to the protection of the equipment itself, it is necessary to isolate the equipment from each other by using devices preventing the explosion from spreading, such as ultra-fast sliding Valves, Float Valves ®, chemical barriers or explosion diverters.