Tailor-made solutions for different applications

AIS explosion suppression systems protect your equipment from the damaging effects of flames and pressure generated by an explosion.The protection system instantly detects the explosion at its earliest stage and stops its development before it exceeds the pressure resistance of the equipment.

The explosion is suppressed by releasing an extinguishing agent (extinguishing powder or water) into the protected volume.

The aim is to limit the development of the explosion and thus to minimize its consequences. Workers will then be effectively protected against the effects of pressure, flames and heat released by a traditional explosion vent. Depending on the process, the extinguishing agent can be either powder or superheated and micronized water.

The ATEX safety concept for your plant – Reliable detection

Three essential components to guarantee your safety:

Three essential components to guarantee your safety:

- - Detection and recording – The ATEX PXD detection technology

- - Control and supervision – The ATEX ESXX control unit

- - Suppression to protect your plant – The ATEX AE cylinders

When the suppression system is triggered, the time, pressure and system’s data are permanently stored in the control cabinet to allow a perfect analysis of any incident that might happen.

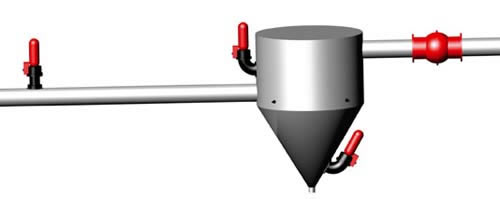

Effective explosion protection - the suppressor

The detection system monitors the equipment to be protected at all times.

When explosion is detected, appropriate measures can be taken to trigger the suppressors.

The detection system monitors the equipment to be protected at all times.

When explosion is detected, appropriate measures can be taken to trigger the suppressors.

In a few milliseconds, a relief valve opens to instantly release the extinguishing agent into the equipment to be protected.

Extinguishing systems absorb the energy of the explosion and locally inert the atmosphere. In this way, with the help of ATEX Suppression Systems, you can suppress an explosion in the initial phase of development.

With the help of our engineers, we will define the most suitable explosion protection solution for the process.

Your benefits – process reliability, low operating costs and fast reconditioning.

- Safety of operators working close to ATEX suppressors through a supervised mechanical locking device of the bottle.- Fast and low-cost bottle reconditioning with reusable trigger device.

- Standard hardware exchange facilitated by quick connections

- Saved time in reconditioning operations

- Safe handling of the triggers, fully encapsulated

- Permanent monitoring of Individually addressed components.

- Complete control of the protection system from the control cabinet or remotely with the ATEX communication modem and worldwide coverage of the ATEX service.

- Continuous and permanent recording of the stored information.

ATEX – Worldwide experience and products

ATEX safety systems have been developed by explosion and fire experts with extensive knowledge of the industry and safety technologies.ATEX explosion safety concepts combine special features of an industrial plant with appropriate protective measures.

This ensures undisturbed operation of your plant, thus increasing its productivity.

The advantages of ATEX systems are worldwide recognized.